Boring & Milling Spindles manufactured by 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, represent a significant advancement in the precision machining industry. These heads are used in a wide variety of applications ranging from high speed milling to high precision machining in different materials, such as metal, plastic and composite materials. The combination of technological innovation and advanced design makes these heads highly versatile and efficient for a wide range of milling and boring operations.

4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, as an industry-leading manufacturer of machining machinery, has earned a strong reputation for its commitment to quality and excellence in engineering. Its Milling & Boring heads incorporate cutting-edge technologies, such as high-efficiency internal cooling systems, precision bearings and high-strength materials, ensuring exceptional performance and long life.

These heads are notable for their ability to deliver an unmatched combination of precision, rigidity and load capacity, making them ideal for applications requiring high-speed, high-precision machining. The tool clamping and changing systems built into these heads enable smooth and efficient operation, resulting in improved productivity and reduced downtime in high-performance manufacturing environments.

Additionally, milling and chuck heads from 4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, offer a wide variety of configuration options, making them suitable to accommodate different machining requirements, from complex contour milling operations to high precision boring. Likewise, the ability to integrate with advanced control systems allows greater automation and precision in machining operations.

In summary, the milling and chuck heads manufactured by4ManPro® (Elements For Manufacturing Processes) a Hann Kuen Machinery & Hardware, Co., Ltd. BRANCH OFFICE, represent a standard of excellence in the precision machining industry. Their unique combination of advanced technology, superior performance and versatility makes them an indispensable choice for manufacturers and operators looking to achieve new levels of productivity and quality in their Milling & Boring operations.

The heads for Boring & Milling are included in the following Series and the elements that compose them are listed below.

ELEMENTS

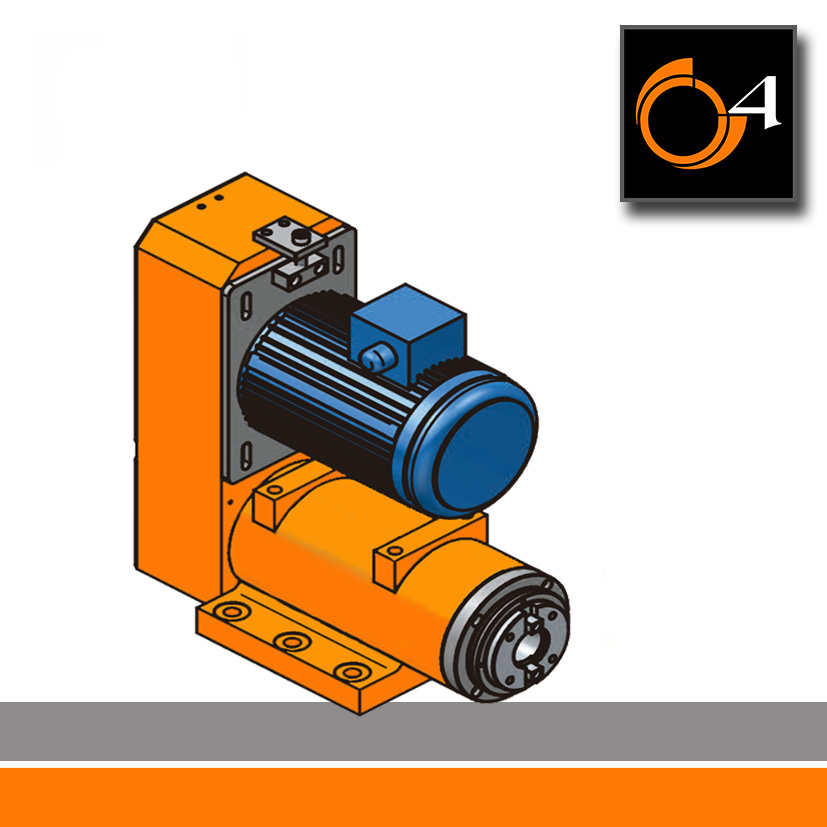

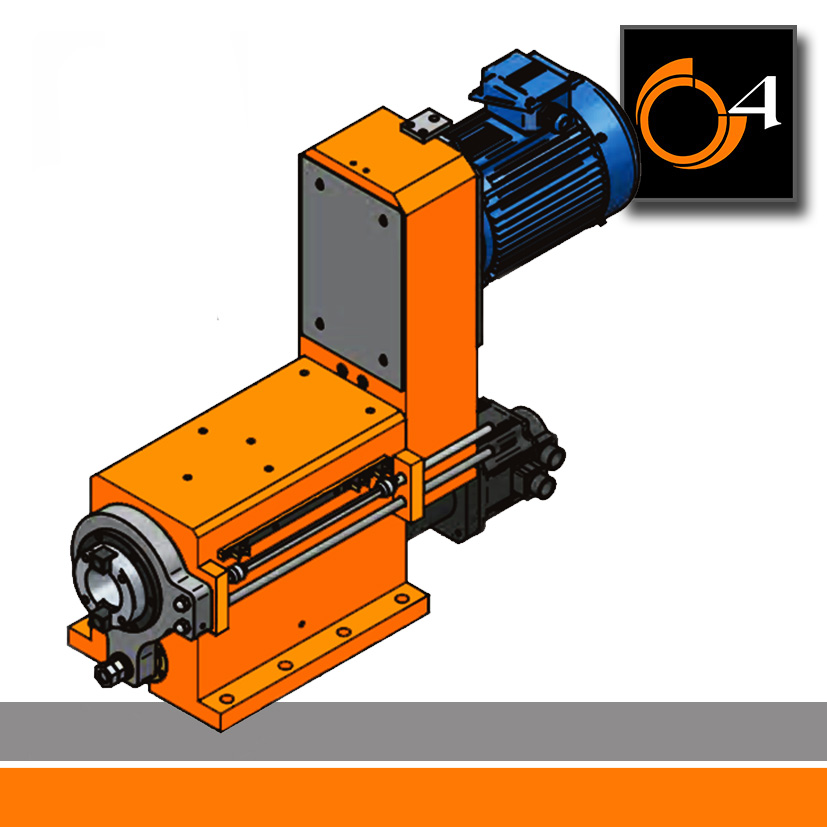

Milling And Boring Heads With Square Spindle Body

- MAXIMUM SPINDLE POWER

- ½, 1, 2, 3, 5, 7.5, 15 & 20 H.P.

- MAXIMUM SPINDLE SPEED (Standard Series)

- 600, 800,1200, 1600, 1800, 2000, 2500, 3000 & 4000 r.p.m.

- MAXIMUM SPINDLE STROKE (H Series)

- 2000, 2500, 3000, 4000, 5000, 6000, 8000, 1000 & 12000 r.p.m.

- NOZZLE TYPES:

- ER-20, ER-32, ER-40, NT-40, NT-50 / A2-6

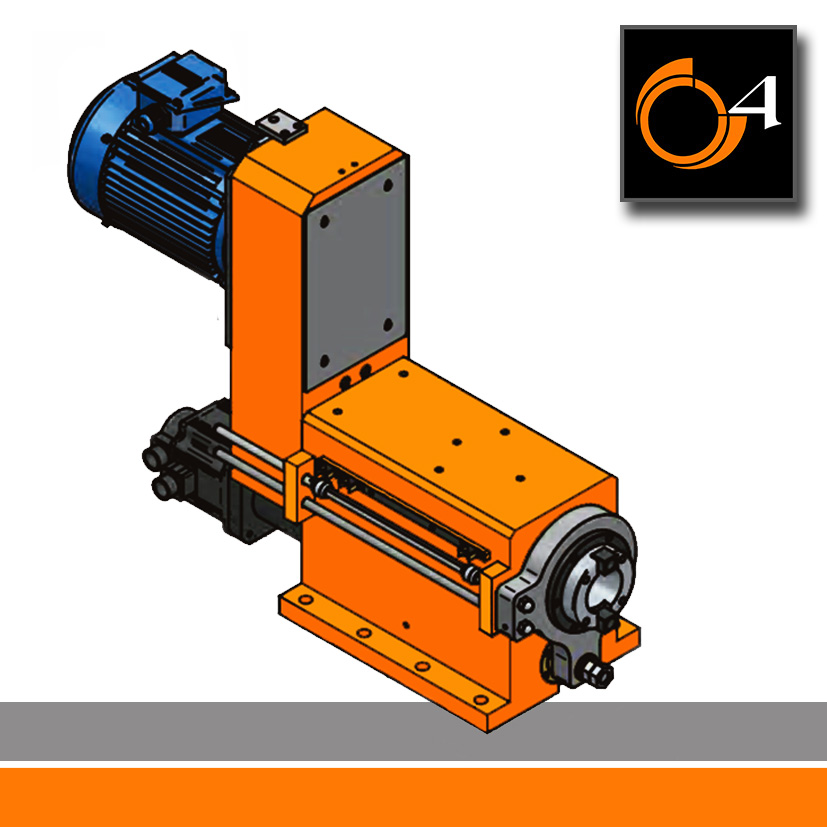

Milling and Boring Heads with Round Spindle Body (Heavy Duty)

- MAXIMUM SPINDLE POWER

- 2, 3, 5 & 7.5 H.P.

- MAXIMUM SPINDLE SPEED (Standard Series)

- 1200, 1800, 2000 & 3000 r.p.m.

- MAXIMUM SPINDLE STROKE (H Series)

- 3000, 5000, 6000, & 1000 r.p.m.

- NOZZLE TYPES:

- NT-30, NT-40 & NT-50 / A2-5

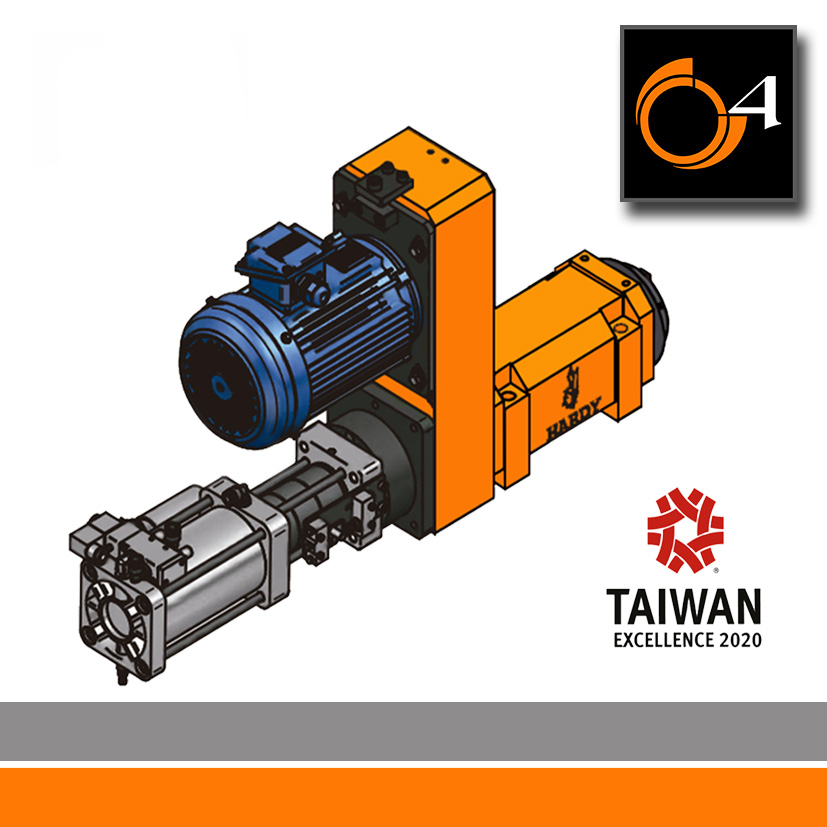

Milling and boring heads with independent body for special high-performance applications

- MAXIMUM SPINDLE POWER

- 1, 2, 3, 5 & 7.5 H.P.

- MAXIMUM SPINDLE SPEED (Standard Series)

- 1200, 1600, 1800, 2000, 2500 & 3000 r.p.m.

- MAXIMUM SPINDLE STROKE (H Series)

- 3000, 4000, 5000, 6000, 8000 & 1000 r.p.m.

- NOZZLE TYPES:

- ER-32, NT-30/ER-32, NT-40, NT-40/A2-5 & NT-50

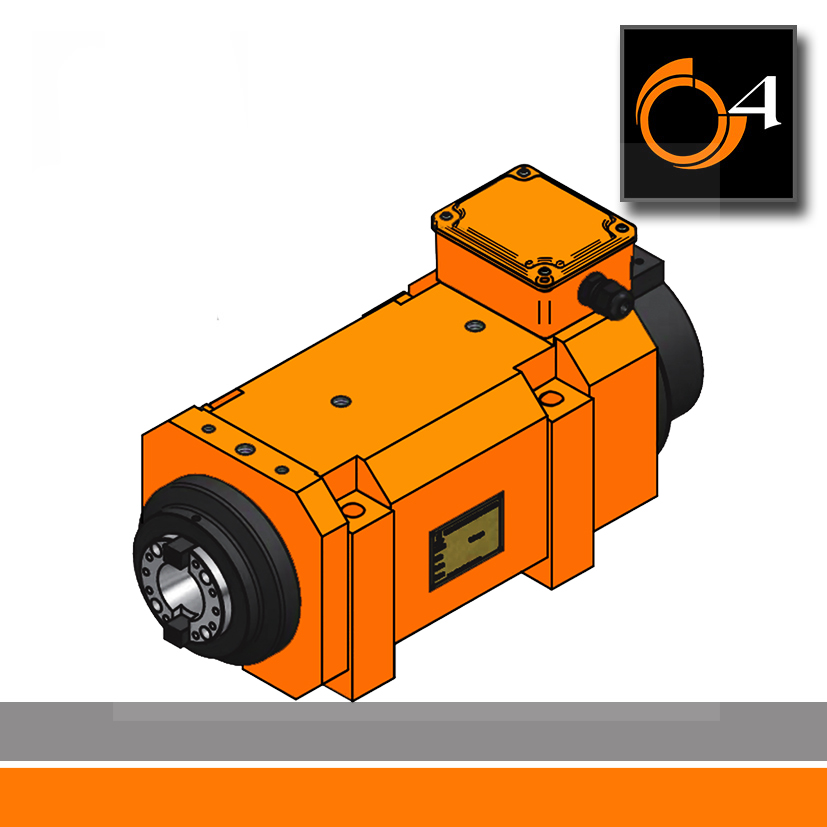

Compact Servo Heads for Milling and Boring, with Oil Cooling System for Continuous Work.

- MAXIMUM SPINDLE POWER

- 2, 3 & 5 H.P.

- MAXIMUM SPINDLE SPEED (Standard Series)

- 1500, 2000 & 2500 r.p.m.

- MAXIMUM SPINDLE STROKE (H Series)

- 2500, 6000, & 8000 r.p.m.

- NOZZLE TYPES

- NT-30, NT-40 & NT-50

- MAXIMUM SPINDLE POWER

- 1.5, 2.2 & 3.7 Kw

- MAXIMUM SPINDLE SPEED (Standard Series)

- 1500, 2000 & 2500 r.p.m.

- MAXIMUM SPEED (H Series)

- 2500, 6000, & 8000 r.p.m.

- MAXIMUM SPINDLE STROKE

- BT-40 & BT-50

- MAXIMUM SPINDLE POWER

- 1.5, 5.2 & 3.7 Kw

- MAXIMUM SPINDLE SPEED (Standard Series)

- 1500 & 2000 r.p.m.

- MAXIMUM SPEED (H Series)

- 3000 & 6000 r.p.m.

- MAXIMUM SPINDLE STROKE

- BT-40 & BT-50

BORING & mILLING SERVO SPINDLES & SERVO SPINDLE HEADS

- MAXIMUM SPINDLE POWER

- ½, 1, 2, 3 & 5 H.P.

- MAXIMUM SPINDLE SPEED (Standard Series)

- 1600, 2000, 3000, 5000 & 10000 r.p.m.

- NOZZLE TYPES:

- Ø6, Ø13, Ø16, Ø25, Ø35 & Ø50 MM.

- MAXIMUM SPINDLE STROKE

- 60, 80, 85, 100, 120 & 150 mm

*** Patent No. M446677

- MAXIMUM SPINDLE POWER

- 1, 2, 3 & 5 H.P.

- MAXIMUM SPINDLE SPEED (High Performance Series)

- 4000, 6000, 8000 & 10000 r.p.m.

- NOZZLE TYPES

- Ø16, Ø25, Ø35 & Ø50 MM.

- MAXIMUM SPINDLE STROKE

- 100, 120 & 150 mm

*** Patent No. M446677

Angle heads, also known as angle attachments, are versatile accessories that mount to the main spindle of a milling or boring machine.

Their main function is to allow machining at angles not accessible with standard mounted tools, usually at or in adjustable intermediate positions relative to the machine’s Z-axis.

These heads incorporate an internal transmission (often gears) that transfers rotation from the machine spindle to a secondary output spindle positioned at an angle.

They are essential for performing side milling, horizontal boring, or drilling operations on inclined faces of a workpiece without the need to reorient it. This reduces setup times and increases accuracy by keeping the workpiece stationary. They come in a variety of designs, including fixed and orientable types, adapting to different machining needs.